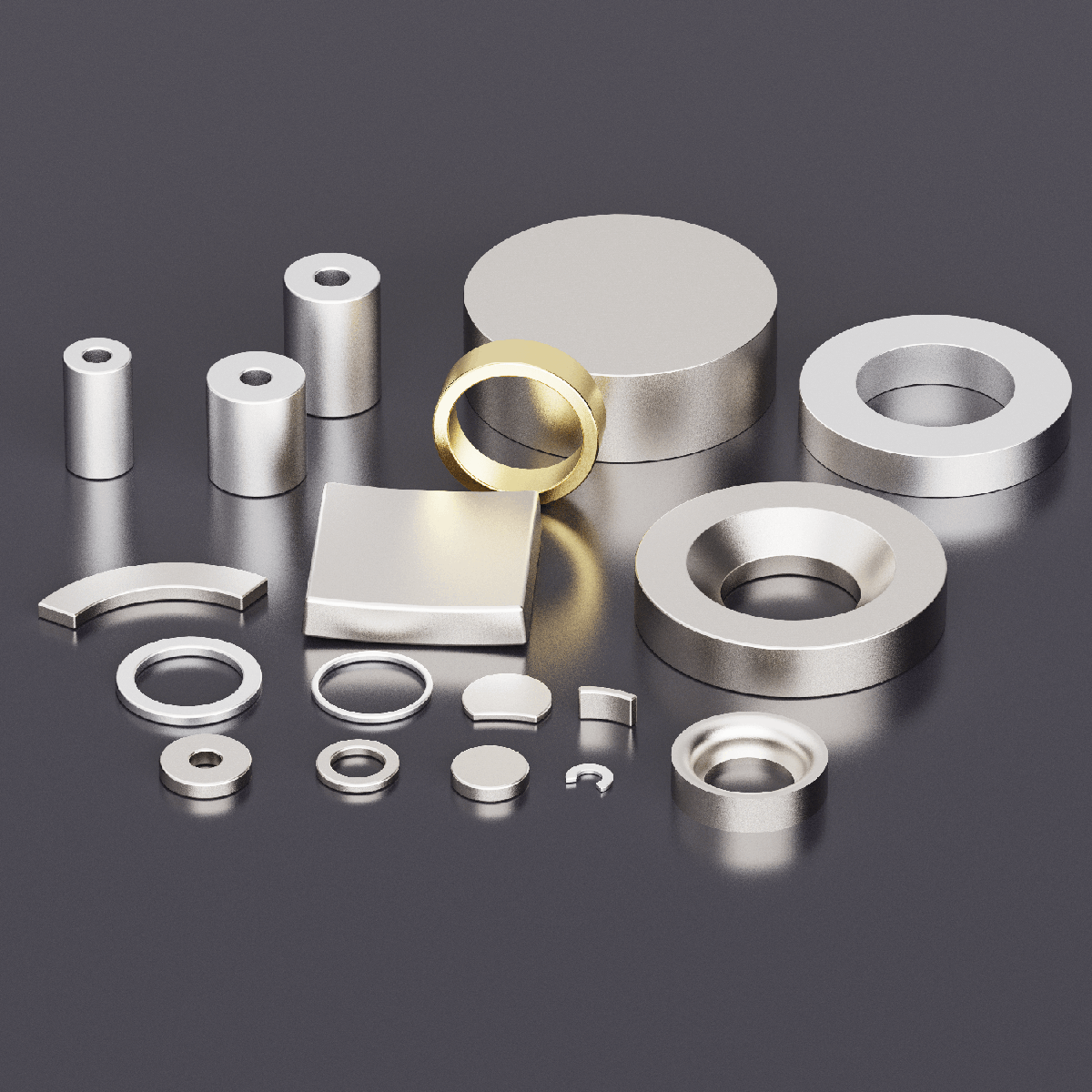

NdFeB magnet is mainly made of Neodymium、Iron and Boron, with excellent magnetic property、abundant raw material and reasonable prices, NdFeB Magnets can be used as an ideal magnet in mini-motor、Permanent magnetic resonance、sound device magnetic suspension system, magnetic transmission machine and iatrical apparatus and etc. For Debits surface is usually treated with some special methods.

The surface treatment method include Zinc、Nickel、Tin、Silver、Gold plating、Phosphor and Spray Epoxy Resin etc.

| Characteristics | Br | Hcb | Hcj | (BH)max | Max. WorkingTemperature |

|---|---|---|---|---|---|

| Grade | T | kA/m | kA/m | KJ/m3 | ℃ |

| N35 | 1.17-1.22 | ≥868 | ≥955 | 33-36 | 80 |

| N38 | 1.22-1.25 | ≥899 | ≥955 | 36-39 | 80 |

| N40 | 1.25-1.28 | ≥907 | ≥955 | 38-41 | 80 |

| N42 | 1.28-1.32 | ≥915 | ≥955 | 40-43 | 80 |

| N45 | 1.32-1.38 | ≥923 | ≥955 | 43-46 | 80 |

| N48 | 1.38-1.42 | ≥923 | ≥955 | 46-49 | 80 |

| N50 | 1.4-1.45 | ≥955 | ≥876 | 48-51 | 80 |

| N52 | 1.43-1.48 | ≥876 | ≥876 | 50-53 | 80 |

| N54 | 1.45-1.50 | ≥876 | ≥876 | 52-55 | 70 |

| N35M | 1.17-1.22 | ≥868 | ≥1114 | 33-36 | 100 |

| N38M | 1.22-1.25 | ≥899 | ≥1114 | 36-39 | 100 |

| N40M | 1.25-1.28 | ≥923 | ≥1114 | 38-41 | 100 |

| N42M | 1.28-1.32 | ≥955 | ≥1114 | 40-43 | 100 |

| N45M | 1.32-1.38 | ≥995 | ≥1114 | 43-46 | 100 |

| N48M | 1.37-1.43 | ≥1027 | ≥1114 | 46-49 | 100 |

| N50M | 1.40-1.45 | ≥1033 | ≥1114 | 48-51 | 100 |

| N52M | 1.43-1.48 | ≥1043 | ≥1114 | 50-53 | 100 |

| N35H | 1.17-1.22 | ≥868 | ≥1353 | 33-36 | 120 |

| N38H | 1.22-1.25 | ≥899 | ≥1353 | 36-39 | 120 |

| N40H | 1.25-1.28 | ≥923 | ≥1353 | 38-41 | 120 |

| N42H | 1.28-1.32 | ≥955 | ≥1353 | 40-43 | 120 |

| N45H | 1.32-1.37 | ≥973 | ≥1353 | 43-46 | 120 |

| N48H | 1.37-1.42 | ≥995 | ≥1353 | 46-49 | 120 |

| N50H | 1.40-1.45 | ≥1003 | ≥1353 | 48-51 | 120 |

| N35SH | 1.17-1.22 | ≥876 | ≥1592 | 33-36 | 150 |

| N38SH | 1.22-1.25 | ≥907 | ≥1592 | 36-39 | 150 |

| N40SH | 1.25-1.28 | ≥939 | ≥1592 | 38-41 | 150 |

| N42SH | 1.28-1.32 | ≥963 | ≥1592 | 40-43 | 150 |

| N45SH | 1.32-1.38 | ≥979 | ≥1592 | 43-46 | 150 |

| N48SH | 1.37-1.43 | ≥1011 | ≥1592 | 46-49 | 150 |

| N28UH | 1.04-1.08 | ≥764 | ≥1990 | 26-29 | 180 |

| N30UH | 1.08-1.13 | ≥812 | ≥1990 | 28-31 | 180 |

| N33UH | 1.13-1.17 | ≥852 | ≥1990 | 31-34 | 180 |

| N35UH | 1.17-1.22 | ≥860 | ≥1990 | 33-36 | 180 |

| N38UH | 1.22-1.25 | ≥899 | ≥1990 | 36-39 | 180 |

| N40UH | 1.25-1.28 | ≥939 | ≥1990 | 38-41 | 180 |

| N42UH | 1.28-1.32 | ≥963 | ≥1990 | 40-43 | 180 |

| N45UH | 1.32-1.38 | ≥979 | ≥1990 | 43-46 | 180 |

| N28EH | 1.04-1.08 | ≥780 | ≥2388 | 26-29 | 200 |

| N30EH | 1.08-1.13 | ≥812 | ≥2388 | 28-31 | 200 |

| N33EH | 1.13-1.17 | ≥836 | ≥2388 | 31-34 | 200 |

| N35EH | 1.17-1.22 | ≥876 | ≥2388 | 33-36 | 200 |

| N38EH | 1.22-1.25 | ≥899 | ≥2388 | 36-39 | 200 |

| N40EH | 1.25-1.28 | ≥923 | ≥2388 | 38-41 | 200 |

| N42EH | 1.28-1.32 | ≥931 | ≥2388 | 40-43 | 200 |

| N28AH | 1.04-1.08 | ≥787 | ≥2624 | 26-29 | 230 |

| N30AH | 1.08-1.13 | ≥819 | ≥2624 | 28-31 | 230 |

| N33AH | 1.13-1.17 | ≥843 | ≥2624 | 31-34 | 230 |

| N35AH | 1.17-1.22 | ≥876 | ≥2624 | 33-36 | 230 |

| N38AH | 1.22-1.25 | ≥899 | ≥2624 | 36-39 | 230 |

| N40AH | 1.25-1.28 | ≥923 | ≥2624 | 38-41 | 230 |